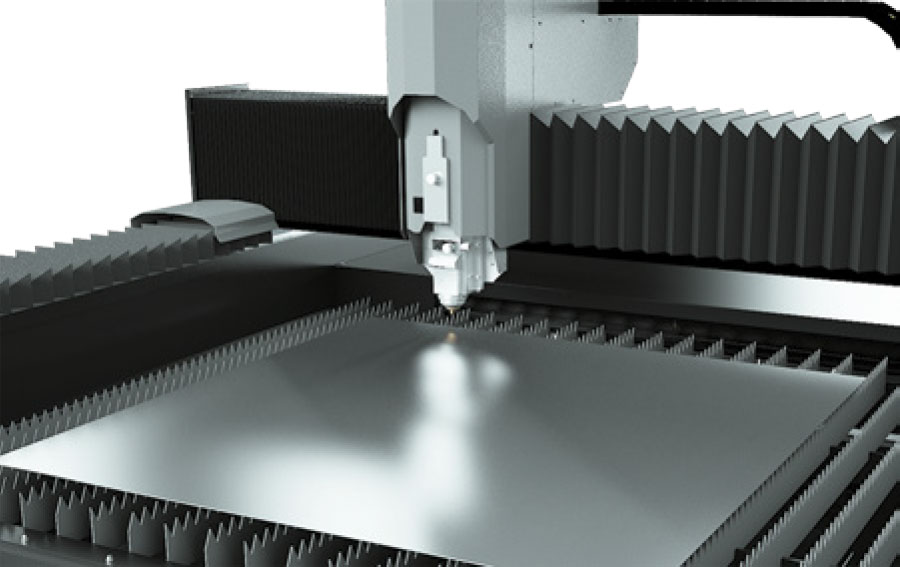

JMT Eco Fiber Laser Series

STANDARDS

– Mechanically robust and rigid body

– Rack & Pinion servo motorized positioning system

– 4 Axis digital motor system

– Built-in discharges slag cars

– Fume extraction system

– Automatic dual pallet exchange table

– Automatic focus cutting head

– Air Blowing System

– Protective Glass (2 pieces)

– Power Automation touch screen control unit

– Radan Profile CAD or Lantek Expert Cut Software

– Light curtain safety barriers for shuttle table

OPTIONS

– IPG resonator (0,5kw, 1kw, 2kw) with chiller

– Camera System with Display

– Filter system

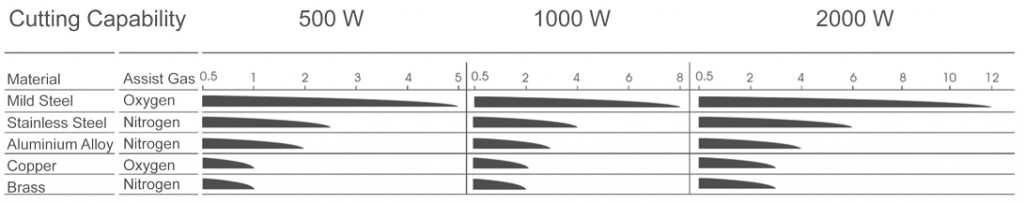

Compact & Economic

When you choose JMT ECO Series Fiber Laser, you choose the most compact & easy to operate laser machine. JMT Eco Fiber Laser is designed to provide you quality and fast cutting from 0.5 mm to 12 mm with low power consumption. The Eco comes in three different power choices 500 W, 1 kW, 2 kW. All Components are gathered at a single body with its compact and ergonomic construction. The Eco offers a dual pallet system for higher work efficiency. Laser cutting is being used for an increasing number of applications in sheet metal processing and represents a unique quality. High precision of the dimensions and minimum heat distortion of the sheet parts are just two of the advantages that convince the user of the first class cutting results and ability to cut mild steel, stainless steel, aluminium, copper, brass and titanium which provides stable parameters and reliable process results. All important technical components and all system parts are specially developed and result from proprietary activities. Our equipment is so easy to operate that even with no experience you will quickly be able to cut the highest quality parts.

– No Mirrors

– No Glassware

– No Warm-up Time

– No Loss of Power

– No Turbine/Fans

– No Vacuum Pump

– No Beam Divergence

– No Mirror Adjustment

– Compact

– Easy to operate

– Higher cutting speeds

– Low power consumption

– Wide choice of contours,

sheet thicknesses

– Dual work table integration

for faster loading